Magnetic Materials Introduction

Magnetic Materials Introduction

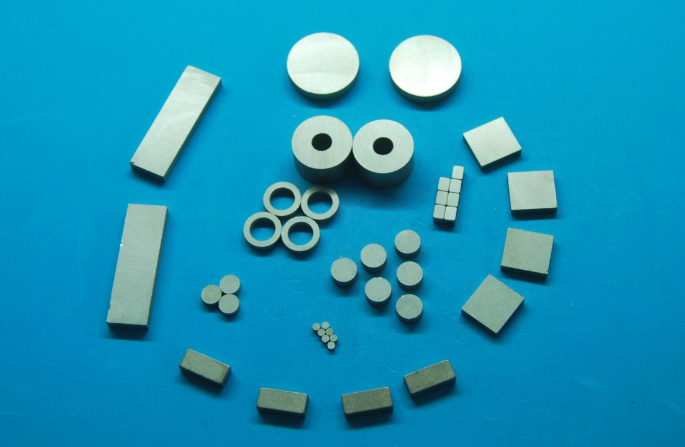

Materials Introduction

Ferrites Commonly known as Ceramics, have been in production since the 1950’s. They are primarily made from Iron Oxide (FeO) and the addition of Sr and Ba through a calcining process. They are the least expensive and most common of all magnet materials. Primary grades are C1, C5 and C8. They are mostly used in motors and sensors.

Alnico These are one of the oldest commercially available magnets and have been developed from earlier versions of magnetic steels. Primary composition is

Al, Ni and Co, hence the name. Although they have a high remanent induction, they have relatively low magnetic values because of their easy of demagnetization. However, they are resistant to heat and have good mechanical features. Common applications are in measuring instruments and high temperature processes such as holding devices in heat treat furnaces.

Samarium Cobalt They belong to the rare earth family because of the Sm and Co elements in their composition. Magnetic properties are high and they have very good temperature characteristics. They are also more expensive than the other magnet materials. They come mostly in two grades: SmCo5 and Sm2Co17, also known as SmCo 1:5 and 2:17. Common uses are in aerospace, military and medical industries.

Neodymium Also known as Neo, these are the strongest and most controversial magnets. They are in the rare earth family because of the Nd, B, Dy, Ga elements in their composition. A relatively new group of commercial magnets, they are controversial because they are the only magnets that have been patented for both composition and processing. The patent and licensing issues are important and will be discussed later in this guide.

Bonded Magnets All of the above materials are available as bonded grades by either extrusion, compression, calendaring or injection molding processes. The magnetic properties are lower because they sometimes lose their anisotropy and they are not fully dense due to the introduction of resins and epoxies. The main advantage to this group is that they can be made in complex shapes and can be insert, over-molded and co-molded with other materials.