Daily Use Powerful NdFeB Magnet

|

|

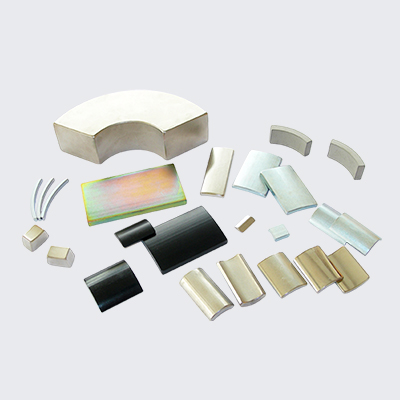

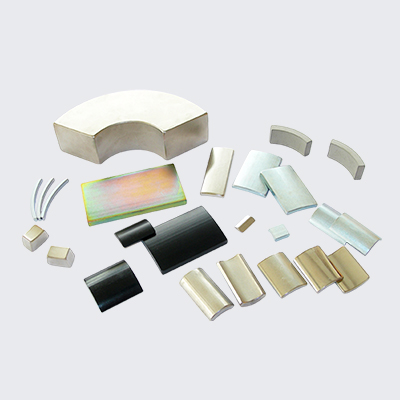

| Neodymium Magnet (NdFeB magnet) for motor, generator, driver in various specification | Tile-shaped and special-shaped Neodymium Magnet (NdFeB magnet) |

|

|

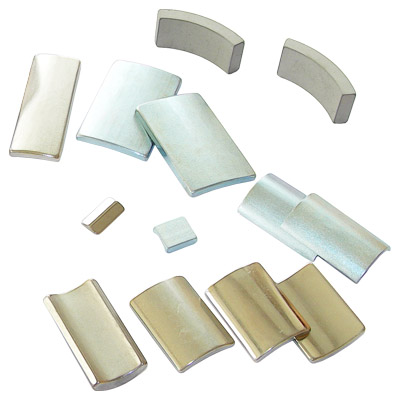

| Neodymium Magnet Blocks in various specification | Neodymium Magnet products painted with epoxy resin |

|  |

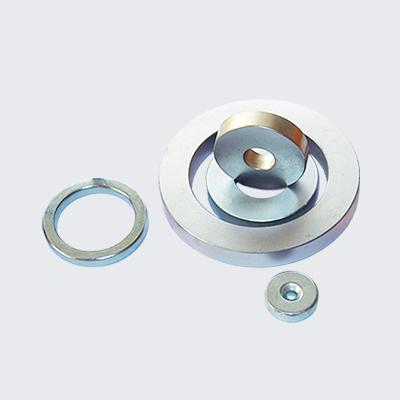

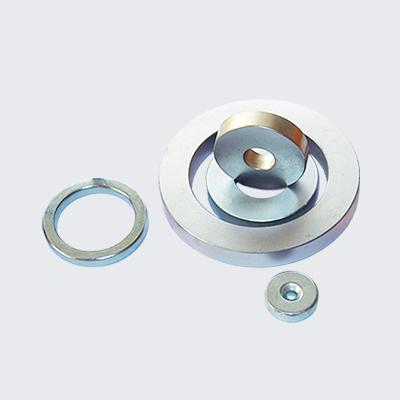

| Neodymium Magnet Rings in various specification | Neodymium Magnet Cylinders in various specification |

|

|

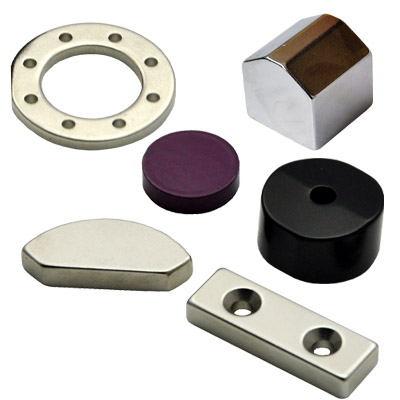

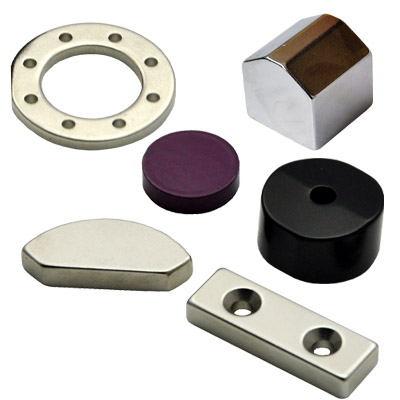

| Special Shape of Neodymium Magnet | Rubber Coated Neodymium Magnet |

|  |

| Special Shape of Neodymium Magnet | QQMAG: Amazing Magnetic Sphere |

Magnetic properties of Sintered Neodymium Magnet (NdFeB magnet):

| Grade | Remanence | Coercive Force | Intrinsic

Coercive Force | Max. energy

product | Max.

Operating

Temperature |

Br

mT

(kGs) | Hcb

kA/m

(kOe) | Hcj

kA/m

(kOe) | ( BH )max kJ/m3

(MGOe) | Tw |

| N35 | 1170-1220 | ≥ 868 | ≥ 955 | 263-287 | 80 ℃ |

| (11.7-12.2) | ( ≥ 10.9) | ( ≥ 12) | (33-36) |

| N38 | 1220-1250 | ≥ 899 | ≥ 955 | 287-310 | 80 ℃ |

| (12.2-12.5) | ( ≥ 11.3) | ( ≥ 12) | (36-39) |

| N40 | 1250-1280 | ≥ 907 | ≥ 955 | 302-326 | 80 ℃ |

| (12.5-12.8) | ( ≥ 11.4) | ( ≥ 12) | (38-41) |

| N42 | 1280-1320 | ≥ 915 | ≥ 955 | 318-342 | 80 ℃ |

| (12.8-13.2) | ( ≥ 11.5) | ( ≥ 12) | (40-43) |

| N45 | 1320-1380 | ≥ 923 | ≥ 955 | 342-366 | 80 ℃ |

| (13.2-13.8) | ( ≥ 11.6) | ( ≥ 12) | (43-46) |

| N48 | 1380-1420 | ≥ 923 | ≥ 876 | 366-390 | 80 ℃ |

| (13.8-14.2) | ( ≥ 11.6) | ( ≥ 12) | (46-49) |

| N50 | 1400-1450 | ≥ 796 | ≥ 876 | 382-406 | 60 ℃ |

| (14.0-14.5) | ( ≥ 10.0) | ( ≥ 11) | (48-51) |

| N52 | 1430-1480 | ≥ 796 | ≥ 876 | 398-422 | 60 ℃ |

| (14.3-14.8) | ( ≥ 10.0) | ( ≥ 11) | (50-53) |

| 30M | 1080-1130 | ≥ 796 | ≥ 1114 | 223-247 | 100 ℃ |

| (10.8-11.3) | ( ≥ 10.0) | ( ≥ 14) | (28-31) |

| 33M | 1130-1170 | ≥ 836 | ≥ 1114 | 247-263 | 100 ℃ |

| (11.3-11.7) | ( ≥ 10.5) | ( ≥ 14) | (31-33) |

| 35M | 1170-1220 | ≥ 868 | ≥ 1114 | 263-287 | 100 ℃ |

| (11.7-12.2) | ( ≥ 10.9) | ( ≥ 14) | (33-36) |

| 38M | 1220-1250 | ≥ 899 | ≥ 1114 | 287-310 | 100 ℃ |

| (12.2-12.5) | ( ≥ 11.3) | ( ≥ 14) | (36-39) |

| 40M | 1250-1280 | ≥ 923 | ≥ 1114 | 302-326 | 100 ℃ |

| (12.5-12.8) | ( ≥ 11.6) | ( ≥ 14) | (38-41) |

| 42M | 1280-1320 | ≥ 955 | ≥ 1114 | 318-342 | 100 ℃ |

| (12.8-13.2) | ( ≥ 12.0) | ( ≥ 14) | (40-43) |

| 45M | 1320-1380 | ≥ 995 | ≥ 1114 | 342-366 | 100 ℃ |

| (13.2-13.8) | ( ≥ 12.5) | ( ≥ 14) | (43-46) |

| 48M | 1360-1430 | ≥ 1027 | ≥ 1114 | 366-390 | 100 ℃ |

| (13.6-14.3) | ( ≥ 12.9) | ( ≥ 14) | (46-49) |

| 50M | 1400-1450 | ≥ 1033 | ≥ 1114 | 382-406 | 100 ℃ |

| (14.0-14.5) | ( ≥ 13.0) | ( ≥ 14) | (48-51) |

| 30H | 1080-1130 | ≥ 796 | ≥ 1353 | 223-247 | 120 ℃ |

| (10.8-11.3) | ( ≥ 10.0) | ( ≥ 17) | (28-31) |

| 33H | 1130-1170 | ≥ 836 | ≥ 1353 | 247-271 | 120 ℃ |

| (11.3-11.7) | ( ≥ 10.5) | ( ≥ 17) | (31-34) |

| 35H | 1170-1220 | ≥ 868 | ≥ 1353 | 263-287 | 120 ℃ |

| (11.7-12.2) | ( ≥ 10.9) | ( ≥ 17) | (33-36) |

| 38H | 1220-1250 | ≥ 899 | ≥ 1353 | 287-310 | 120 ℃ |

| (12.2-12.5) | ( ≥ 11.3) | ( ≥ 17) | (36-39) |

| 40H | 1250-1280 | ≥ 923 | ≥ 1353 | 302-326 | 120 ℃ |

| (12.5-12.8) | ( ≥ 11.6) | ( ≥ 17) | (38-41) |

| 42H | 1280-1320 | ≥ 955 | ≥ 1353 | 318-342 | 120 ℃ |

| (12.8-13.2) | ( ≥ 12.0) | ( ≥ 17) | (40-43) |

| 45H | 1300-1360 | ≥ 963 | ≥ 1353 | 326-358 | 120 ℃ |

| (13-13.6) | ( ≥ 12.1) | ( ≥ 17) | (43-46) |

| 48H | 1370-1430 | ≥ 995 | ≥ 1353 | 366-390 | 120 ℃ |

| (13.7-14.3) | ( ≥ 12.5) | ( ≥ 17) | (46-49) |

| 30SH | 1080-1130 | ≥ 804 | ≥ 1592 | 223-247 | 150 ℃ |

| (10.8-11.3) | ( ≥ 10.1) | ( ≥ 20) | (28-31) |

| 33SH | 1130-1170 | ≥ 844 | ≥ 1592 | 247-271 | 150 ℃ |

| (11.3-11.7) | ( ≥ 10.6) | ( ≥ 20) | (31-34) |

| 35SH | 1170-1220 | ≥ 876 | ≥ 1592 | 263-287 | 150 ℃ |

| (11.7-12.2) | ( ≥ 11.0) | ( ≥ 20) | (33-36) |

| 38SH | 1220-1250 | ≥ 907 | ≥ 1592 | 287-310 | 150 ℃ |

| (12.2-12.5) | ( ≥ 11.4) | ( ≥ 20) | (36-39) |

| 40SH | 1240-1280 | ≥ 939 | ≥ 1592 | 302-326 | 150 ℃ |

| (12.5-12.8) | ( ≥ 11.8) | ( ≥ 20) | (38-41) |

| 42SH | 1280-1320 | ≥ 987 | ≥ 1592 | 318-342 | 150 ℃ |

| (12.8-13.2) | ( ≥ 12.4) | ( ≥ 20) | (40-43) |

| 45SH | 1320-1380 | ≥ 1003 | ≥ 1592 | 342-366 | 150 ℃ |

| (13.2-13.8) | ( ≥ 12.6) | ( ≥ 20) | (43-46) |

| 28UH | 1020-1080 (10.2-10.8) | ≥ 764 | ≥ 1990 | 207-231 | 180 ℃ |

| ( ≥ 9.6) | ( ≥ 25) | (26-29) |

| 30UH | 1080-1130 (10.8-11.3) | ≥ 812 | ≥ 1990 | 223-247 | 180 ℃ |

| ( ≥ 10.2) | ( ≥ 25) | (28-31) |

| 33UH | 1130-1170 | ≥ 852 | ≥ 1990 | 247-271 | 180 ℃ |

| (11.3-11.7) | ( ≥ 10.7) | ( ≥ 25) | (31-34) |

| 35UH | 1180-1220 | ≥ 860 | ≥ 1990 | 263-287 | 180 ℃ |

| (11.8-12.2) | ( ≥ 10.8) | ( ≥ 25) | (33-36) |

| 38UH | 1220-1250 | ≥ 876 | ≥ 1990 | 287-310 | 180 ℃ |

| (12.2-12.5) | ( ≥ 11.0) | ( ≥ 25) | (36-39) |

| 40UH | 1240-1280 | ≥ 899 | ≥ 1990 | 302-326 | 180 ℃ |

| (12.5-12.8) | ( ≥ 11.3) | ( ≥ 25) | (38-41) |

| 28EH | 1040-1090 | ≥ 780 | ≥ 2388 | 207-231 | 200 ℃ |

| (10.4-10.9) | ( ≥ 9.8) | ( ≥ 30) | (26-29) |

| 30EH | 1080-1130 (10.8-11.3) | ≥ 812 | ≥ 2388 | 223-247 | 200 ℃ |

| ( ≥ 10.2) | ( ≥ 30) | (28-31) |

| 33EH | 1130-1170 | ≥ 836 | ≥ 2388 | 247-271 | 200 ℃ |

| (11.3-11.7) | ( ≥ 10.5) | ( ≥ 30) | (31-34) |

| 35EH | 1170-1220 | ≥ 876 | ≥ 2388 | 263-287 | 200 ℃ |

| (11.7-12.2) | ( ≥ 11.0) | ( ≥ 30) | (33-36) |

| 38EH | 1220-1250 | ≥ 899 | ≥ 2388 | 287-310 | 200 ℃ |

| (12.2-12.5) | ( ≥ 11.3) | ( ≥ 30) | (36-39) |

| 30AH | 1080-1120 | ≥ 812 | ≥ 2785 | 223-255 | 220 ℃ |

| (10.8-11.2) | ( ≥ 10.2) | ( ≥ 35) | (28-32) |

| 33AH | 1120-1170 | ≥ 812 | ≥ 2785 | 247-271 | 220 ℃ |

| (11.2-11.7) | ( ≥ 10.2) | ( ≥ 35) | (31-34) |

Physical and Mechanical Properties of Neodymium Magnet:

| Thermal Conductivity | 7.7 kcal/m-h-°C |

| Young’s Modulus | 1.7 x 104 kg/mm² |

| Bending Strength | 24 kg/mm² |

| Compressive Strength | 80 kg/mm² |

| Electrical Resistivity | 160 µ-ohm-cm/cm² |

| Density | 7.4-7.55 g/cm³ |

| Vickers Hardness | 500 - 600 |

Available coatings for sintered Neodymium Magnet (NdFeB magnet):

| Available Coatings: |

| Surface | Coating | Thickness

(Microns) | Color | Resistance |

| Passivation | | 1 | Silver Grey | Temporary Protection |

| Nickel | Ni+Ni | 10-20 | Bright Silver | Excellent against Humidity |

| Ni+Cu+Ni |

| Zinc | Zn | 8-20 | Bright Blue | Good Against Salt Spray |

| C-Zn | Shinny Color | Excellent Against Salt Spray |

| Tin | Ni+Cu+Sn | 15-20 | Silver | Superior Against Humidity |

| Gold | Ni+Cu+Au | 10-20 | Gold | Superior Against Humidity |

| Copper | Ni+Cu | 10-20 | Gold | Temporary Protection |

| Epoxy | Epoxy | 15-25 | Black, Red, Grey | Excellent Against Humidity

& Salt Spray |

| Ni+Cu+Epoxy |

| Zn+Epoxy |

| Chemical | Ni | 10-20 | Silver Grey | Excellent Against Humidity |

| Parylene | Parylene | 5-20 | Grey | Excellent Against Humidity, Salt Spray. Superior Against Solvents, Gases, Fungi and Bacteria.

FDA Approved. |

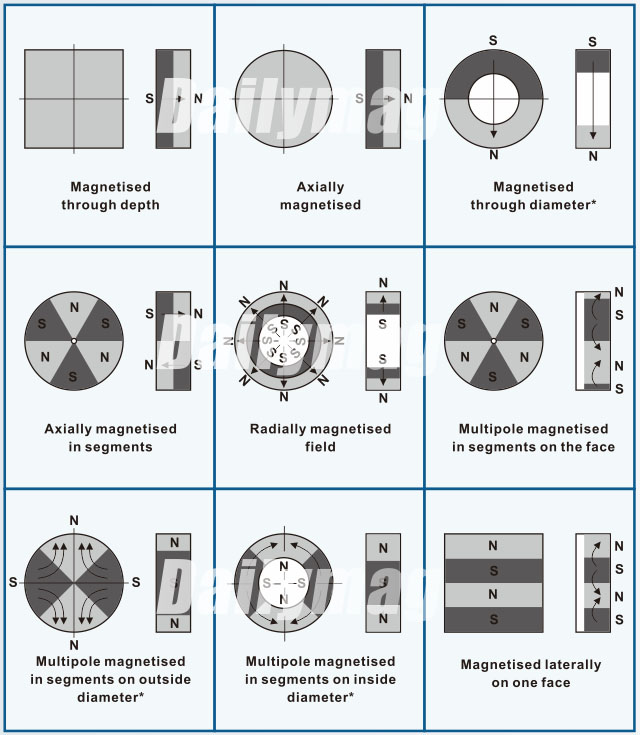

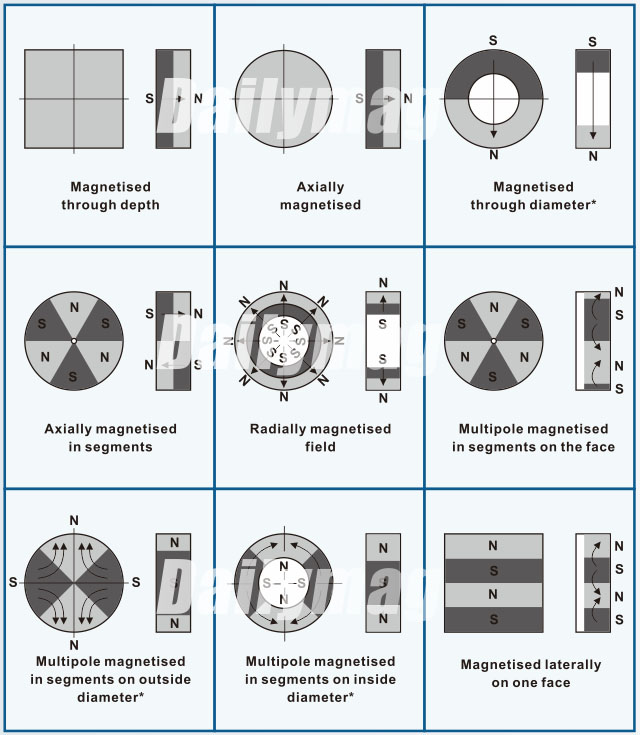

Magnetisation Direction of Magnet

1. Magnetised through depth

2. Axially magnetised

3. Magnetised through diameter*

4. Axially magnetised in segments

5. Radially magnetised

6. Multipole magnetised in segments on the face

7. Multipole magnetised in segments on outside diamater*

8. Multipole magnetised in segments on inside diamater*

9. Magnetised laterally on the face

All available for magnet is isotropic or anisotropic except*

Sintered NdFeB magnets (also known as "neo" magnets) are among the most popular magnets in the market today. The magnets have been available commercially since November 1984. They boast of offering the highest energy product (of any material/magnets today) and are available in a wide variety of sizes, grades and shapes (discs, arcs, blocks, spheres, trapezoid etc.).

Initially, NdFeB magnets were primarily used for making VCM’s (voice coil motors) in hard disk drives. This application still accounts for approximately 55 percent of all total sales of Sintered NdFeB magnets today. The magnets have many other applications due to their reasonable cost and superior magnetic properties. NdFeB magnets are used in making many tools/equipment such as communication tools, computer devices, motors, sensors, speakers and medical treatment instruments just to mention a few tools/equipment.

Sintered NdFeB magnets are made using an intermetallic compound; Nd2Fe14B which is composed of 2 rare earth atoms, one boron atom and 14 iron atoms. Besides the main-phase Nd2Fe14B (in NdFeB materials), there are some small quantities of rare Nd-rich phase (earth-rich phase), boron-rich phase and others. The earth-rich phase pins domain walls to give sintered NdFeB magnets a high coercive force. NdFeB magnets available today commercially have numerous partial alloying Nd and Fe substitution combinations which results in a variety of properties. Moreover, the magnets majorities are anisotropic which simply means they are capable of being magnetized in the orientation direction. Neo magnets are 3rd generation rare earth magnets which are simply the most commercially advanced and powerful magnets in the market today.

Main advantages

Sintered NdFeB magnets emit very deep magnetic fields attracting other magnets and ferrous items from impressive distances. The magnets are extremely strong when you consider factors like size. The magnets are a true representation of what small powerful magnets can do. Small Sintered NdFeB magnets have an unmatched amount of magnetic force. For instance, the magnets are capable of lifting magnets/metals weighing 1,000 times (their own weight).

You are bound to be amazed at the strength of Sintered NdFeb magnets if you haven’t handled neodymium magnets before. The magnets are 10 times stronger than ferrite magnets which are the strongest ceramic magnets. Another notable advantage of the magnets lies in the fact that they come in a variety of shapes the most common being block, ring and disc shapes. It’s also possible to have custom shapes. The magnets have other advantages i.e. their excellent coercive force, high remanences as well as brilliant high energy product.

Application of Neodymium Magnet:

1. Computers: VCM, Printers

2. Machinery: Magnetic separtors, Robots

3. Transportation: Levitation train, Electric vehicle

4. Medical Service: MRI, Magnetic-therapy devices

5. Energy: Genertator, Electric motor

6. Communication: Mobile telephone, Voice and data, Communication system

7. Electical Appliance: HiFi system, Air conditioner

8. Oil Chemical Industry: Magnetic vibrating device for reducing viscosity and condensation, Nuclear magnetic logging tools, Anti-waxer of oil wells

Why is the price of neodymium magnets soaring?

What is a Neodymium Magnet, for starters?

A common rare earth magnet made of neodymium (Nd), iron (Fe), boron (B), and metal complexes is known as a Neodymium (Nd-Fe-B) magnet. Due to their powerful magnetic field, which is 1.4 teslas (T), a unit of magnetic coil or coefficient of permeability, they perform better in applications.

The way neodymium magnets are made determines whether they are sintering or bonded. Since their invention in 1984, they have been the most extensively utilised magnets.

Neodymium is radioactive in its native condition and can only be magnetised at extremely low temperatures. It can be magnetised at ambient temperature when coupled with some other metals, such as iron.

Neodymium and samarium cobalt are the two forms of rare earth magnets. Samarium cobalt magnets were the most often used before the introduction of neodymium magnets, but they were eventually displaced by neodymium magnets due to the high cost of producing samarium cobalt magnets.

Neodymium isn't found in its pure form or immiscible with other lanthanides in nature, thus it's normally refined for application. Despite being classified as a narrow frequency, neodymium is rather abundant, being no more rare than cobalt, nickel, or iron, and is widely dispersed in the Earth's crust. China mines the majority of the country's commercial neodymium.

In 1927, neodymium combinations had first been extensively utilised as glass colors, and they are still a common glass addition today. The hue of neodymium substances is always a bright red, though it varies depending on the type of brightness. This is generally a combination of acute light absorbance peak of magnets with ambient light augmented with the pointed visible emission artists of mercury, trivalent europium, or terbium. Laser beams which transmit infrared having frequencies between 1047 and 1062 nanometers employ neodymium-doped glassware. These have been utilised in increased purposes such as gravitational containment nuclear tests.

What are all the Characteristics of a Neodymium Magnet?

The fundamental feature of neodymium magnets is their strength in relation to their dimensions. The magnetic properties loop happens when a magnetic field is supplied to a neodymium magnet and the molecular dipoles align, resulting in a magnetic field. When the magnetic field is withdrawn from the magnetised neodymium, a portion of the aligning remains.

The magnetic strength of neodymium magnets is determined by their grade. The stronger the magnet's power, the greater the grade rating. The numbers are derived from their qualities, which are given as mega gauss Oersteds or MGOe, which is the most powerful point on its BH Curve.

The "N" grade series runs from N30 to N52, while N52 magnets are rarely employed or only utilised in unusual circumstances. The "N" number may be accompanied by two letters, such as SH, indicating the conductivity of the magnet (Hc). The higher the Hc, the higher the intensity at which the neo magnet will reduce its performance.

●Modify physical attributes

The rare-earth metal neodymium was found in the traditional project to produce at a frequency of about 18%. The shine of metal neodymium is dazzling and gleaming. The change from the double hexagon to a muscle cubic form occurs around 863 ° C., and neodymium is divided into 2 allotropes of carbon. At ambient temperature, neodymium is paramagnetic, but when cooled to 20 K, it becomes antiferromagnetic. It is alloying elements with steel, which is a ferromagnet, to create neodymium magnets.

●Chemical characteristics

At room temperature, neodymium iron rapidly fires to generate neodymium(III) oxides; the oxide peels off, revealing the main metal to further corrosion.

●Various traditions

The atomic dipole antennas align when neodymium is subjected to a magnetic field. A fraction of the orientation remains after being withdrawn from the field, resulting in magnetic neodymium. The flow pattern that stays when the external field is reduced from concentration to zero is known as remanence, which is also known as residual magnetization. The purpose as conventional is related to the flow velocity.

What is the process of making neodymium magnets?

Sintering and bonding are the two methods utilised to make neodymium magnets. The qualities of final magnets depend greatly on how they are made, with sintering being the most effective of the two procedures.

Sintering

●Melting: To make an alloy, the Neodymium, Iron, and Boron are calculated out and placed in a vacuum electric furnace. Additional elements, including cobalt, copper, gadolinium, and dysprosium, are incorporated for products specifically to help with corrosion. To keep impurities out, electrical eddy currents generate heat in a vacuum. Each producer and grade of neodymium magnet has an unique neo alloy composition.

●Powdering: Once the alloy has melted, it is chilled and shaped into bars. To make a micron-sized powder, the ingots are jet processed in a nitrogen and argon environment. For pounding, neodymium dust is placed in a feed.

●Pressing: The material is subjected to a magnetic field during pressing. It is then pushed into a larger form in a second die, aligning the magnets perpendicular to the press orientation. Fixtures that generate earth's magnetic field while pressing are used in some approaches to align the atoms.

●Sintering, also called frittage, is the procedure of squeezing and creating a green magnetic using heat less than its melting point of giving it its ultimate magnetic properties. In an inert, oxygen-free environment, the process must be carefully controlled.

●Machining: To shape sintered magnets to the necessary tolerances, diamond or wire saws are used to form them.

●Plating & coating: Because neodymium oxidises quickly and is susceptible to corrosion, its electromagnetic characteristics might well be lost. Plastic, nickel, copper, zinc, tin, and other types of coverings are used to preserve them.

●Magnetization: Despite having a magnetization direction, the magnet is not magnetised and must be temporarily introduced to a powerful magnetic field, which is created by a loop of wire surrounding the magnet.

●Final Inspection: Dimensions are verified using digital measuring projectors, and the thickness of the plating is verified using x-ray fluorescence equipment. Other tests are performed on the coating to confirm its quality and robustness. A hysteresis graph is used to ensure full amplification of the BH curve.

Bonding

The epoxy and neodymium combination is either pressed or extruded and baked to cure. Magnets can be moulded into complicated forms and configurations because the solution is squeezed onto a die or extruded. Compression bonding creates magnetism with close tolerances without the need for additional procedures.

Isotropic compressive bonded magnets can be magnetised in any orientation, including multi-polar arrangements. Due to the sheer epoxy binding, the magnets can be machined or lathed but not tapped or pierced.

What is the price of neodymium magnets?

The price of neodymium magnets has risen due to a little fluctuation in the market. Let's see why is the price of neodymium magnets soaring?

Neodymium prices have surged in the last month, increasing anxiety and concern in the global hi-tech markets. The fundamental cause of this price increase is a significant buyers and sellers discrepancy.

To begin with, rare earth producers did not operate at maximum capacity in the first half of 2020, resulting in low input materials stocks among magnet manufacturers, particularly during the summer months. Furthermore, due to the increased proliferation of the covid-19 virus, the market has plummeted.

Conversely, the market for smart components such as fuel cells, cell phones, screens, elevated batteries, and electromagnets suddenly grew by around 20% in the second quarter of the year. It's enough to say that demand for permanent magnets for wind turbines and other green energy gadgets has more than doubled.

●The demand for neodymium magnets has skyrocketed.

The need for neodymium magnets has risen dramatically in industries such as electric vehicles and wind power, which require them in their products. The higher price of neodymium magnets is partly due to these efforts targeted at energy transition.

●The Cost of transportation is increasing.

The expansion in online trading as a result of Covid-19 has resulted in a tremendous surge in sales for container shipping from China. Furthermore, due to a scarcity of flights, passenger aircraft cargo capabilities have decreased. Transportation expenses are increasing as a result of these developments.

●A increasing RMB real exchange against the US dollar

All purchases with Chinese producers are settled in US dollars, as is common in international shopping. However, since the Chinese currency, the RMB (RMB = Renminbi Yuan), has become much stronger against the US dollar in the course of the Chinese economy's quick rebound following the shutdown last year, already high raw material costs have been exacerbated by the money influence. It is around -7 percent higher than last year and is contributed to the appraised value by the suppliers, who pay for basic production and industrial costs in RMB. At this time, it's uncertain when the strong economic statistics from the United States will help the rate of exchange.

Dailymag encourages making clients have access as soon as possible, putting the goods in the stock, to get a permanently locked price that is not influenced by future rises. Designers are constantly adjusting advancements in the situation because of collaborations with prominent manufacturers, and are devoted to immediately informing our customers about market dynamics.