Sintered SmCo Magnet

intered SmCo Magnet (SmCo Magnets) is biggest advantage is its high working temperature -350℃,in general ,magnetizing field of approximately 30 to 45 KOe are required. SmCo magnet is widely used in motors, meters, transducers, instruments, positional detector, generators , wind power generators, radar and other applications.

We are professional Manufacturer of Sintered SmCo Magnet and SmCo Magnets in china.

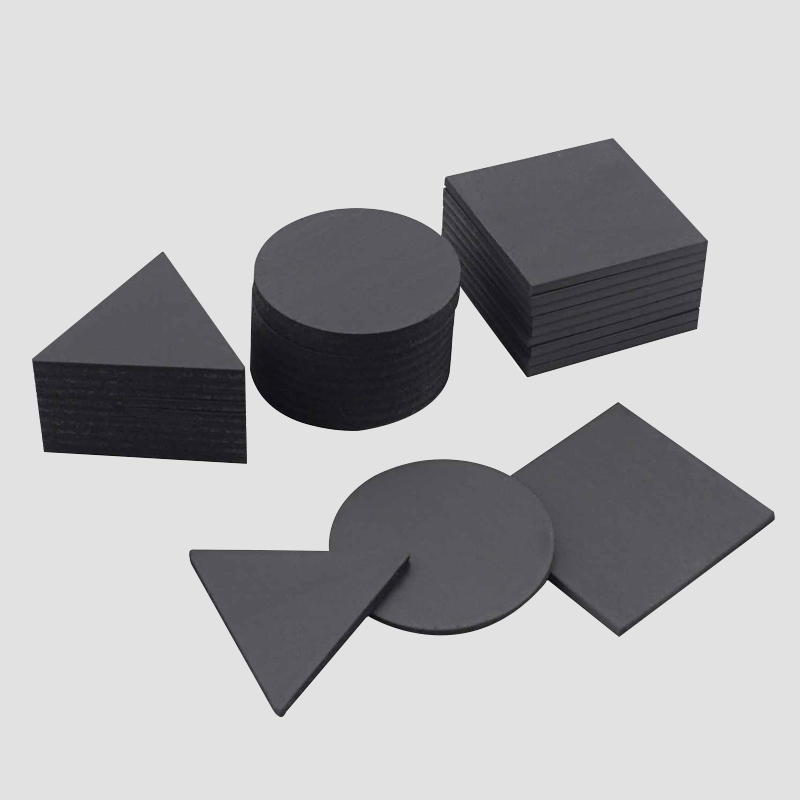

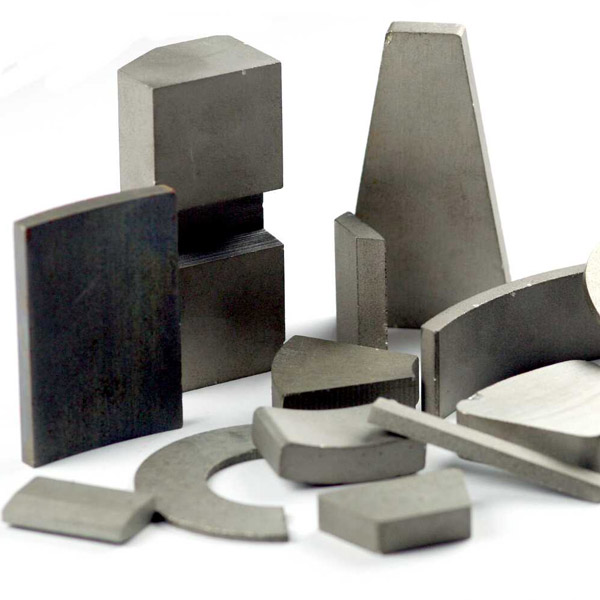

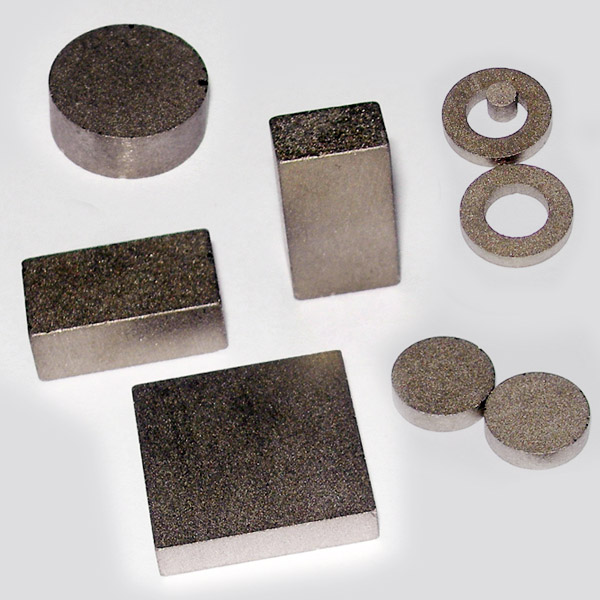

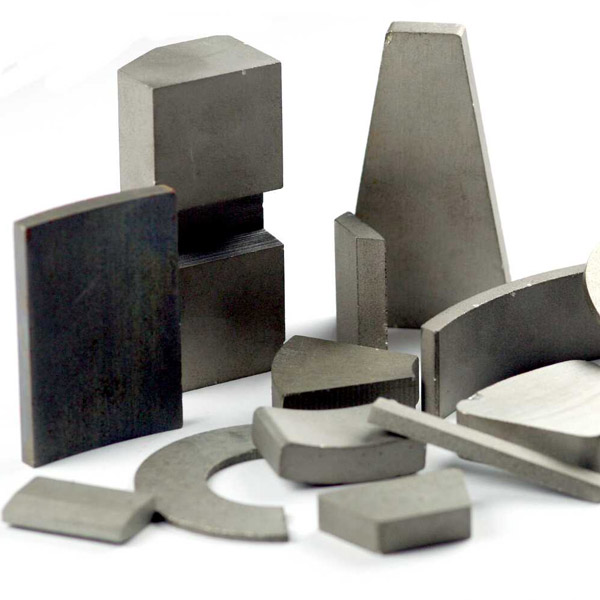

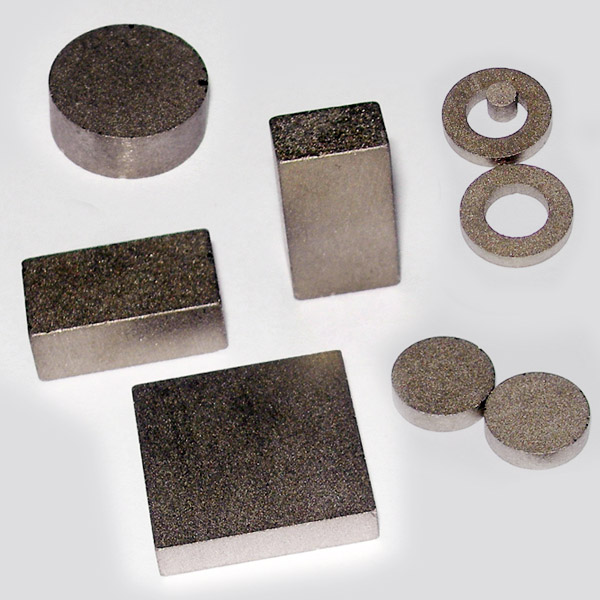

What shapes can it be formed with Sintered SmCo magnet? Sintered SmCo Magnet

|  |

|  |

Magnetic properties of SmCo5 (Sintered SmCo Magnet)

| Material | Grade | Remanence | Coercive Force | Intrinsic Coercive Force | Max. energy product | Curie Temperature | Max. Operating Temperature | Temperature Coefficient of Br | Temperature Coefficient of Hc | ||||

| Br | Hcb | Hcj | (BH)max | Tc | Tw | ||||||||

| SmCo5 (Smpr)co5 | T | KGs | KA/m | KOe | KA/m | KOe | KJ/m3 | MGoe | °C | °C | %°C | %°C | |

| YX- 16 | 0.81-0.85 | 8.1- 8.5 | 620-660 | 7.8- 8.3 | 1194-1830 | 15-23 | 110-127 | 14-16 | 750 | 250 | -0.05 | -0.3 | |

| YX- 18 | 0.85-0.9 | 8.5- 9.0 | 660-700 | 8.3- 8.8 | 1194-1830 | 15-23 | 127-143 | 16-18 | 750 | 250 | -0.05 | -0.3 | |

| YX- 20 | 0.9-0.94 | 9.0- 9.4 | 680-725 | 8.5-9.1 | 1194-1830 | 15-23 | 150-167 | 19-21 | 750 | 250 | -0.05 | -0.3 | |

| YX- 22 | 0.92-0.96 | 9.2- 9.6 | 710-750 | 8.9-9.4 | 1194-1830 | 15-23 | 160-175 | 20-22 | 750 | 250 | -0.05 | -0.3 | |

| YX- 24 | 0.96-1.0 | 9.6- 10.0 | 730-770 | 9.2-9.7 | 1194-1830 | 15-23 | 175-190 | 22-24 | 750 | 250 | -0.05 | -0.3 | |

| SmCo5 | YX- 20s | 0.9-0.94 | 9.0- 9.4 | 680-725 | 8.5-9.1 | 1433-1830 | 18-23 | 143-160 | 18-20 | 750 | 250 | -0.05 | -0.3 |

| YX- 22s | 0.92-0.96 | 9.2- 9.6 | 710-750 | 8.9-9.4 | 1433-1830 | 18-23 | 160-175 | 20-22 | 750 | 250 | -0.05 | -0.3 | |

| Low temperature coefficient SmCo5 (SmGd)Co5 | LTc (YX- 10) | 0.59-0.63 | 5.9- 6.3 | 460-493 | 5.8-6.2 | 1430-1830 | 18-23 | 68-80 | 8.5-10 | 700 | 250 | Temperature | Temperature Coefficient of Br %°C |

| 20-100°C | -0.004 | ||||||||||||

| 100-200°C | -0.021 | ||||||||||||

| 200-300°C | -0.042 | ||||||||||||

| ce(coFecu)5 | YX- 12 | 0.70-0.74 | 7.0- 7.4 | 358-390 | 4.5-4.9 | 358-478 | 4.5-6 | 80-103 | 10-13 | 450 | 200 | ||

Magnetic properties of Sm2Co17 (Sintered SmCo Magnet)

| Material | Grade | Remanence | Coercive Force | Intrinsic Coercive Force | Max. energy product | Curie Temperature | Max. Operating Temperature | Temperature Coefficient of Br | Temperature Coefficient of Hc | ||||

| Br | Hcb | Hcj | (BH)max | Tc | Tw | ||||||||

| Sm2Co17 Sm2 (CoFecuzr)17 | YXG- 24H | 0.95-1.02 | 9.5- 10.2 | 700-750 | 8.7-9.4 | =1990 | =25 | 175-191 | 22-24 | 800 | 350 | -0.03 | -0.2 |

| YXG- 26H | 1.02-1.05 | 10.2- 10.5 | 750-780 | 9.4-9.8 | =1990 | =25 | 191-207 | 24-26 | 800 | 350 | -0.03 | -0.2 | |

| YXG- 28H | 1.03-1.08 | 10.3- 10.8 | 756-796 | 9.5-10 | =1990 | =25 | 207-220 | 26-28 | 800 | 350 | -0.03 | -0.2 | |

| YXG- 30H | 1.08-1.10 | 10.8- 11.0 | 788-835 | 9.9-10.5 | =1990 | =25 | 220-240 | 28-30 | 800 | 350 | -0.03 | -0.2 | |

| YXG- 24 | 0.95-1.02 | 9.5- 10.2 | 700-750 | 8.7-9.4 | =1433 | =18 | 175-191 | 22-24 | 800 | 300 | -0.03 | -0.2 | |

| YXG- 26 | 1.02-1.05 | 10.2- 10.5 | 750-780 | 9.4-9.8 | =1433 | =18 | 191-207 | 24-26 | 800 | 300 | -0.03 | -0.2 | |

| YXG- 28 | 1.03-1.08 | 10.3- 10.8 | 756-796 | 9.5-10 | =1433 | =18 | 207-220 | 26-28 | 800 | 300 | -0.03 | -0.2 | |

| YXG- 30 | 1.08-1.10 | 10.8- 11.0 | 788-835 | 9.9-10.5 | =1433 | =18 | 220-240 | 28-30 | 800 | 300 | -0.03 | -0.2 | |

| YXG- 26M | 1.02-1.05 | 10.2- 10.5 | 750-780 | 9.4-9.8 | 955-1273 | 12-16 | 191-207 | 24-26 | 800 | 300 | -0.03 | -0.2 | |

| YXG- 28M | 1.03-1.08 | 10.3- 10.8 | 756-796 | 9.5-10.0 | 955-1273 | 12-16 | 207-220 | 26-28 | 800 | 300 | -0.03 | -0.2 | |

| YXG- 30M | 1.08-1.10 | 10.8- 11.0 | 788-835 | 9.9-10.5 | 955-1273 | 12-16 | 220-240 | 28-30 | 800 | 300 | -0.03 | -0.2 | |

| YXG- 28L | 1.02-1.08 | 10.2- 10.8 | 398-445 | 5.0-5.6 | 400-520 | 5.2-6.5 | 207-220 | 26-28 | 800 | 250 | -0.03 | -0.2 | |

| YXG- 30L | 1.08-1.15 | 10.8- 11.5 | 398-445 | 5.0-5.6 | 400-520 | 5.2-6.5 | 220-240 | 28-30 | 800 | 250 | -0.03 | -0.2 | |

| Low temperature coefficient Sm2Co17 (SmEr)2 (CoTM)17 | LTC (YXG- 22) | 0.94-0.98 | 9.4- 9.8 | 668-715 | 8.4-9.0 | 1194-1591 | 15-20 | 167-183 | 21-23 | 840 | 300 | Temperature | Temperature Coefficient of Br %°C |

| -50-25°C | +0.005 | ||||||||||||

| 20-100°C | +0.012 | ||||||||||||

| 100-200°C | +0.006 | ||||||||||||

| 200-300°C | -0.025 | ||||||||||||

Characteristic comparisons of permanent magnetic materials:

| Materials | (BH)max | Hcj | Br Tc | (Working temperature)max | Anti-causticity |

| SmCo1:5 | 16-25 | 15-25 | -0.05 | 200-250 | Good |

| SmCo2:17 | 22-30 | 6-30 | -0.03 | 300-350 | Good |

| NdFeB | 26-52 | 12-30 | -0.11 | 80-200 | Bad |

| Ferrite magnet | 3-4.5 | 3-4.5 | -0.19 | 200-300 | Good |

| AINiCo | 5-10 | 1-1.8 | -0.03 | 450-500 | Excellent |

Process Flow:

Raw material-----Mixing-----Melting-----Power-----Pressing-----Sintering----Magnetic Inspection-----Cutting and Grinding-----Inspection-----Packing and Shipping

Sintered SmCo Magnet, SmCo Permanent Magnet, Magnetic Material for you now

Magnets with Superior Heat Resistance for High-Performance Applications

Many people ask why there is a SmCo magnet. Well, let me tell you! This is one of the most rare earth magnets out there to date. It's exceptionally difficult to produce, and it's also difficult to create something that can hold up against the high temperatures that it requires for production. There are many different benefits of having this metal magnet in your possession, including its ability to resist corrosion and high temperatures whereas other types of magnets cannot.

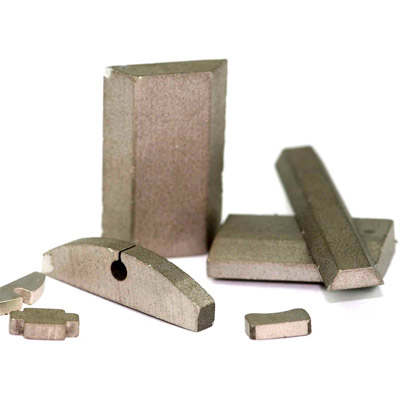

Other benefits include its unmatched level of magnetic strength, which is higher than any other type of magnet on earth. There are many reasons why someone may need this magnet, including the fact that they are available in different shapes and sizes which include out-of-round, discs, blocks, balls, rings or other custom shapes.

Permanent magnets made of samarium cobalt are incredibly strong. Provided with multiple magnets, which are part of the rare-earth magnet family, are comparable in strength to neodymium magnets but have far better temperature stability and coercivity. They can work in temperatures as high as 525°F (300°C). Furthermore, they have a strong resistance to corrosion and demagnetization. These magnets come in a variety of forms, sizes, and grades to meet a variety of characteristics and application needs.

Magnets made of Samarium Cobalt on a custom basis

This is a rare earth magnet and it has a lot of benefits. When you use these magnets you can be sure that your work will be easier and become more efficient. These magnets are known to be the strongest of all types of magnets. You can make sure that they can help you with something, even if they are pretty small depending on what you need at the moment. For example, if you want to mount something on the wall or ceiling of your room then these magnetic hooks will definitely come in handy.

Custom samarium cobalt magnets and quality magnetism assemblies are a specialty of Integral Magnetic waves, which specialises in technical design, development, manufacture, assembly, and testing. We create sophisticated magnetic assemblies for elevated purposes on a regular basis, either according to a create or an architecture basis.

Manufacturing

In most cases, the alloys are processed in their electrically neutral condition. Wet grinding using moisture coolants and a diamond grinding wheel is recommended for the magnet. When drilling holes or other constrained features, the same procedure is necessary. Because these magnets have a low ignition point, the grinding waste must not be allowed to dry entirely. Combustion may be easily started with a little spark, such as that created by static electricity. The fire that results can be quite intense and difficult to manage.

These magnets are very strong magnets. They are made from neodymium iron boron giving it its power. It has a magnetic force of 40 Maximum Energy Product (BHmax) along with a coercivity rating of 12220 Oe which is higher than other neodymium magnets. It is a rare earth magnet with a peak field strength of 3.1 Amps/m at 2 KHz which is higher than other neodymium magnets. There are many shapes available for it including rounds, rectangles, discs, octahedrons and larger blocks with twice the average dimensions of most neodymium magnets. They can be made into rods that are up to 26 inches long.

All these magnets are made using the reducing and minimisation methods. Because it is used to make these kinds of different magnets, the decrease procedure will be detailed. The raw ingredients are melted in an argon-filled electric furnace. To make an ingot, the mixture is poured into a mould and cooled with water. The iron nugget is crushed, then the particles are processed again to reduce particle size even further. The material is then squeezed onto a die of the appropriate form under a magnetic field to align the atoms' earth's magnetic field.

Applications

Some of the main uses of this magnet include industrial, medical and technical applications where superior strength, pinpoint accuracy and higher resistance to demagnetization are important factors. Its mechanical strength makes it useful in many different applications including: ball bearings, tool holders, and actuators for lightly loaded precision equipment.

Some high-end headphones, such as the Ross RE-278, featured samarium–cobalt "Super Magnet" loudspeakers in the mid-1980s.

Additional applications involve:

●In slot car racing, large voltage motors are employed in the most competitive divisions.

●Turbomachinery

●Magnetic magnets for commuting tubes

●Demand for greater the system to operate at cryogenic or extremely high temperatures (more than 180 °C)

●Temperature-constant competence is critical in applications where performance is expected to be consistent across time.

●NMR spectrometers on a tabletop

●Magnet actuators are rotary technologies that allow them to execute the job of a magnetic actuator.

Advantages

This magnet is a type of rare earth magnet and has the highest amount of magnetic pull. It is produced by the sintered combination of cobalt, chromium, and copper into a single alloy. Unlike other magnets where the magnetic field lines are visible under an electron microscope, for this magnet it's too small to be seen.

●Compared to other types of rare earth magnets, these magnets can hold up to four times as much weight.

●They are typically made from one inch lengths with a diameter about 0.125 inches which make them ideal for use in batteries or loudspeaker manufacturing.

●When used in speakers, they create a higher pitch than other magnets. They can also be used for medical applications, water pumps, gyroscopes, and satellite phone base stations.

●Life expectancy for these magnets is about 20 years.

Disadvantage

One of the disadvantages of using this magnet is that it cannot be demagnetized without special equipment and takes a lot of time to do so, whereas other types of rare earth magnets can easily be demagnetized by a slight shift in the magnetic field. This makes it a very inconvenient material for those looking to dispose of them as they're difficult to remove from whatever they're stuck on.